And Safety Audit

Pallet Rack Inspection & Safety Audit

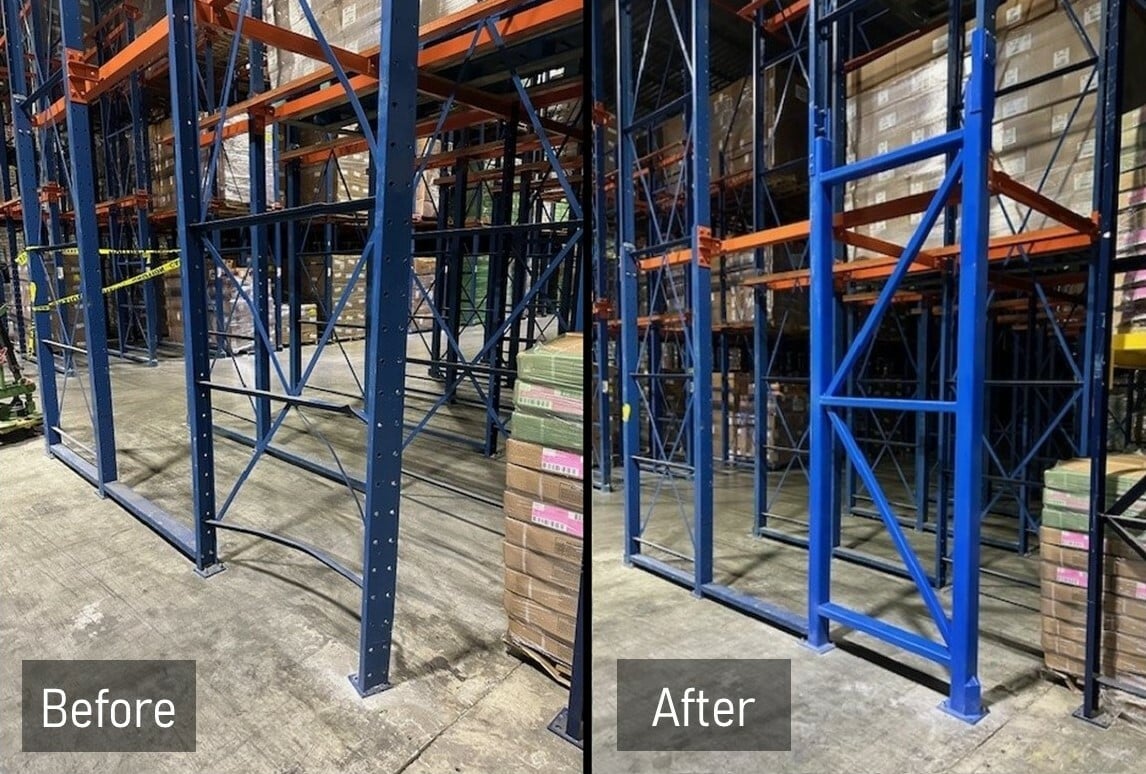

By addressing damaged pallet racking promptly and effectively, businesses can extend the lifespan of their storage systems, enhance workplace safety, and optimize warehouse efficiency. Regular maintenance and inspection schedules are essential for identifying and addressing repair needs proactively.

A pallet racking safety inspection audit is an extensive evaluation of pallet racking systems in a warehouse or storage facility to ensure compliance with safety regulations and identify potential hazards. It is recommended to have annual maintenance visits by a professional rack inspector to ensure your racking can stay loaded at full capacity. We offer a comprehensive Rack Safety Inspection and Audit. Our professional rack expert will come on-site to conduct a thorough inspection of your racking system. This inspection will include viewing upright column, horizontal and diagonal struts, cross beams, anchors, footplates, and decking for any damage. We will then provide you with a clear and easy to read audit report. Our detailed report will include location, description of damage, severity level of damage, and recommendations for repair or replacement. Our report will also include the need for additional protection products, such as end-of-row guards, post protectors, and guardrails, that will secure the integrity of your racking system. Here’s how the audit process typically unfolds:

Assessment

Conducting a thorough inspection to identify damaged or compromised areas of the pallet racking system.

Evaluation

Assessing the severity of the damage and determining the appropriate repair solutions based on factors such as the extent of damage, rack configuration, and load requirements.

Component Replacement

Replacing damaged components such as uprights, beams, braces, connectors, or footplates with new or compatible parts.

Reinforcement

Strengthening weakened or vulnerable areas of the rack system with additional supports, braces, or reinforcements.

Welding and Fabrication

Performing welding or fabrication work to repair bent or twisted components, reinforcing connections, or fabricating custom solutions for specific repair needs.

Anchoring and Stability

Ensuring that the rack system is properly anchored to the floor and meets safety standards for stability and load-bearing capacity.

Safety Compliance

Ensuring that all repairs comply with relevant safety regulations, standards, and manufacturer guidelines to minimize the risk of accidents and injuries.

Preventive Maintenance

Implementing preventive maintenance measures to address potential issues before they escalate into more significant problems, such as regular inspections, repairs, and employee training.

Pallet Rack Repair

Factory and Custom

Pallet rack repair refers to the process of fixing or restoring damaged pallet racking systems in warehouses or storage facilities. These repairs are essential for maintaining the structural integrity and safety of the racks, preventing accidents, and ensuring the efficient operation of the warehouse. Safety is important for any business and a damaged pallet rack can pose serious concerns. We can repair your damaged pallet racking uprights with repair kits that are many times stronger than factory legs which drastically decreases future damage. We offer many solutions to repair pallet racking uprights including repair legs and bracing replacement. Other repair solutions include upright and beam replacement, our installation team will work with you to ensure as little disruption to your daily operation as possible. We also offer custom-made repair solutions to meet your racking needs.

Planning

Determine the scope and objectives of the inspection audit, including the areas to be assessed, the frequency of inspections, and the personnel involved.

Documentation Review

Review relevant documentation, including manufacturer specifications, installation records, load capacity charts, and maintenance logs, to understand the design and history of the pallet racking systems.

Visual Inspection

Conduct a visual inspection of the pallet racking systems, examining each component for signs of damage, wear, or improper installation. Key areas to inspect include uprights, beams, braces, connectors, baseplates, and anchoring.

Load Capacity Assessment

Verify that the racks are loaded within their specified weight limits and that the weight distribution is even across the shelves. Check for overloading, uneven stacking, or improperly placed items that could compromise the stability of the racks.

Anchoring & Stability Check

Ensure that the racks are securely anchored to the floor and that all anchor bolts are properly tightened. Check for any signs of movement or instability that could indicate inadequate anchoring.

Aisle Clearances

Confirm that there are adequate clearances in aisles for safe movement of forklifts, pallet jacks, and other equipment. Check for obstructions, protruding objects, or poor visibility that could impede traffic flow and increase the risk of collisions.

Rack Configuration Review

Assess the overall layout and configuration of the racks, including beam and upright spacing, beam levels, aisle widths, and clearance heights. Ensure that the layout conforms to safety standards and allows for safe and efficient access to stored items.

Safety Accessories Inspection

Check the presence and condition of safety accessories such as rack guards, column protectors, end-of-aisle guards, and safety signage. Ensure that these accessories are installed correctly and functioning as intended to protect against impacts and accidents.

Employee Training & Awareness

Evaluate employee training programs and awareness initiatives related to pallet racking safety. Ensure that employees are knowledgeable about safe loading practices, proper use of equipment, and emergency procedures.

Documentation and Reporting

Document the findings of the inspection audit, including any observed deficiencies, recommendations for corrective actions, and follow-up plans. Prepare a detailed report summarizing the inspection results and outlining actionable steps to address identified issues.

By conducting regular pallet racking safety inspection audits and addressing any concerns promptly, businesses can create a safer working environment, minimize the risk of accidents, and maintain compliance with safety regulations.

Ram Rack

Protection & Repair Products

See what products we offer.

See what products we offer.

WANT TO LEARN MORE

Contact us about your project.